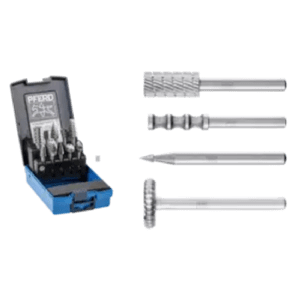

Carbide Burrs

Carbide burrs, also known as carbide rotary files, are cutting tools used in various industries for precision material removal, shaping, and finishing applications. They are typically made from tungsten carbide, a hard and durable material known for its high heat resistance and excellent cutting performance. Carbide burrs feature a cylindrical or conical shape with sharp, fluted edges that allow for efficient stock removal and precise shaping of different materials.

The flutes or grooves on carbide burrs are strategically designed to facilitate chip evacuation during the cutting process, preventing clogging and ensuring smooth operation. These cutting edges are capable of removing material quickly and effectively, making carbide burrs highly efficient tools for tasks such as deburring, chamfering, grinding, and shaping of metal, wood, plastic, and composite materials.

Carbide burrs are available in various shapes and sizes to suit different applications. Common shapes include cylindrical, ball-shaped, tree-shaped, and conical burrs, each designed for specific cutting tasks. They can be mounted on rotary tools, die grinders, or flexible shaft machines, enabling operators to access hard-to-reach areas and achieve precise results.