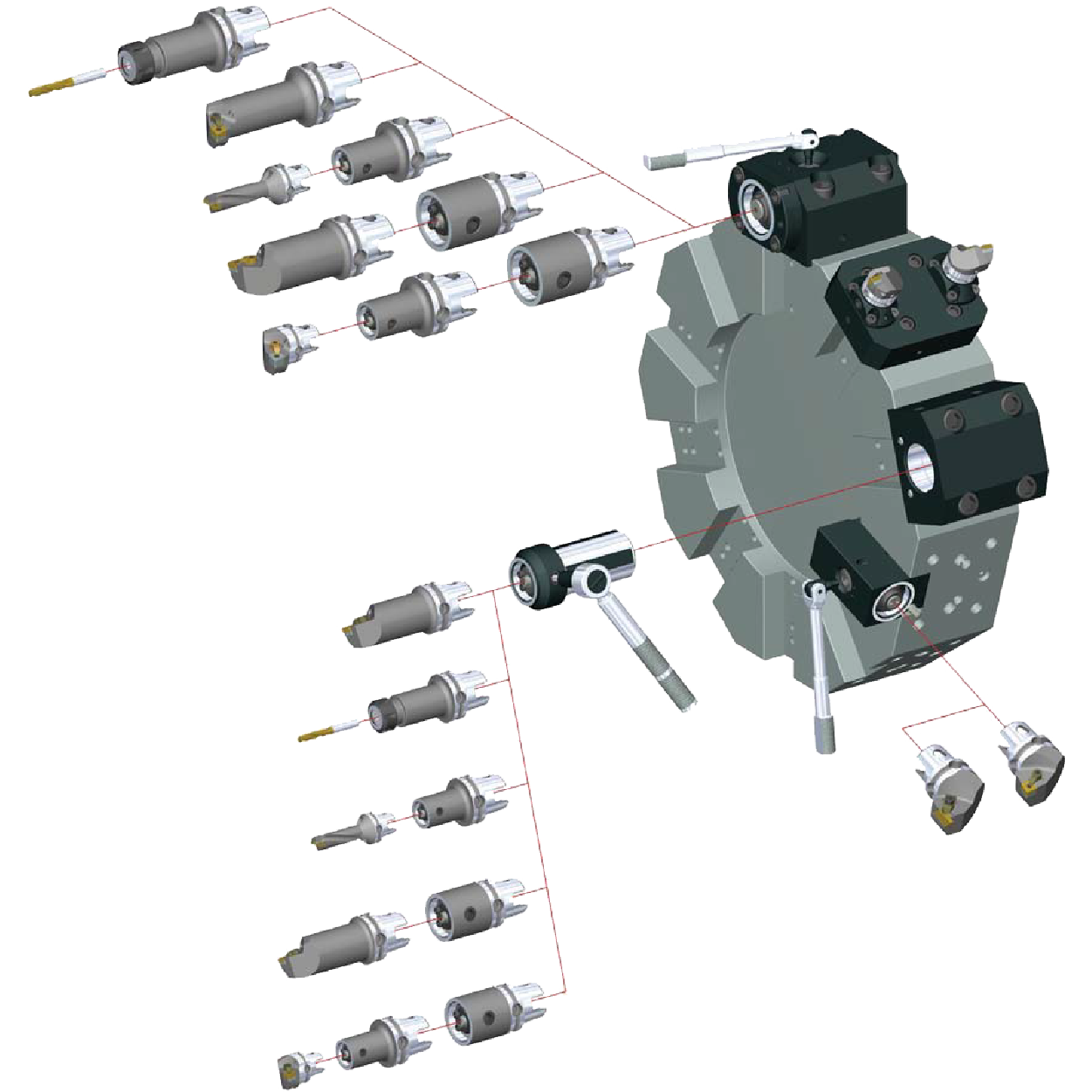

KENNAMETAL MODULAR (KM™) QUICK CHANGE

Visit kennametal.com or kennametal.com/novo for more details.

KM™ quick-change tooling helps achieve dramatic improvements in cutting tool performance and machine output. Frequent changing, setting up, and gaging of tools create costly machine downtime. KM quick-change tooling provides a more efficient process that can reduce downtime to increase productivity.

In addition, KM micro and KM mini systems can be used to considerably increase machine tool capacity on automatic and universal lathes and decrease indexing and setup times by up to 66%. Whether you’re looking to outfit a new machine or improve the output of current equipment, KM quick-change tooling can maximise production.

The KM portfolio includes options for all application requirements and limits the need for costly custom solutions due to system modularity.